It is an admitted fact that water has become scarce resource for the highly populous mega cities and needs to be conserved, lest the taps go dry.

Design Engineers world over are working to find out innovative ways and means for Conserving Water. In such a scenario the Outstanding Design Features of APOLLO’S VEE WIRE FILTER SCREEN KIT has made it the PREFERRED CHOICE in RAIN WATER HARVESTING SYSTEM as it easily stands out against the Conventional, Cumbersome and Costly System in use all these years.

APOLLO’S VEE WIRE FILTER SCREEN comes with BIS (Bureau of India Standards) Code No. 8110 : 2000

Apollo Vee Wire Filter Screen/ Rainwater Filters are the best Rainwater Harvesting Filters which are used for Filtration purpose. These filters have Continuous slots, which are Non Choking & Non Clogging and makes Filtration process smooth. There is no wastage of rain water after using this RWH filter. VEE-WIRE SCREENS is a Proven Product of Proven Technology Trusted Widely for RAINWATER HARVESTING.

With APOLLO VEE-WIRE SCREENS, we are proud to Offer one of the Most Modern Filtration Systems for Rainwater Harvesting (Absolutely Zero Maintenance Cost) with the sole aim of increasing awareness about the Long Term benefits of Rainwater Harvesting using Filter Screens instead of the Conventional Method normally adopted.

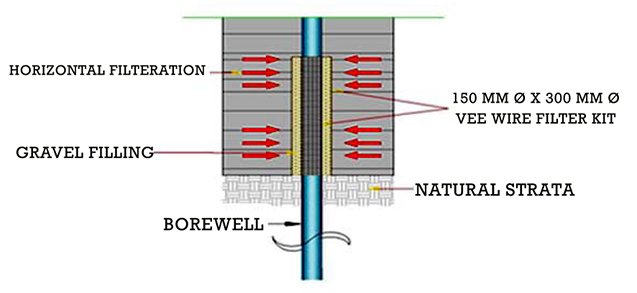

"V-Wire Screen Filter"/ Rainwater Harvesting Filter Screen is a Highly Acceptable Modern Technology in Rain Water Harvesting. It eliminates conventional filtration system, SAVES -Precious Space, Construction Cost and Construction Time for Filtration Tank. Scientific Design helps Cleaning Very Easy and SAVES Maintenance Cost.

VEE-Wire Filter Screens are fabricated in Pipe Form from Wires.

All Welded Wedge Wires Screen is made from 2 elements - outside V-shape Wire and inside Longitudinal Rods.

The V-shaped Wire is spirally wrapped on a cage made of Longitudinal Rods.

The intersecting of shaped wire and rod is welded through each other by resistance welding. Due to resistance welding the weld joined is very strong.

Effectively Filters out maximum suspended solids from raw water with non clogging slots for sutained rechange rate.

Made From Stainless Steel And Suitable for Acid treatment to remove incrustation, chocking of gravles which ENSURES LONG LIFE of borewell.

SAVES MONEY, TIME & ENERGY.

Customised for small or very large roof top area

Compared to any Slotted pipes gives - MAXIMUM RECHARGE RATE at minimum frictional head loss which also reduces incrustation rate

Produces jetting effect to inject recharge water into the aquifer.

|

Details

|

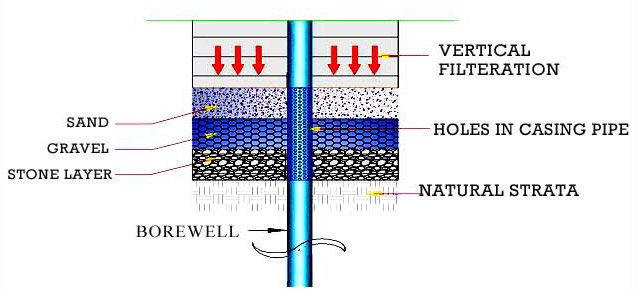

CONVENTIONAL DESIGN

|

APOLLO VEE WIRE FILTER SCREEN DESIGN

|

|---|---|---|

|

CONTINUOUS SLOTS

|

Slots are scattered

|

SPECIAL Design gives Continuous Slot Opening

across the periphery and length of screen.

|

|

NON CLOGGING SLOTS

|

Highly susceptible to clogging due to

vertically settling impurities in water and floating matters which reduces

permeability of filter media

|

V-shape Wire which gives Inwardly Widening

V-shape Slots. This shape does not give space for any sand particle to get

stuck inside the slot and hence these screens are non clogging and this

keeps the Efficiency of tube well maintained over number of years.

|

|

VERY LARGE % OPEN AREA

|

Less Open Area.

|

The Special Design gives Continuous Slot and

hence the % of Open Area for water to enter is more than 2 times that of

conventional slotted pipes of same size and slot opening. This allows more

water to enter at much lesser frictional head loss and the efficiency of

tube well is improved appreciably.

|

|

BETTER SAND FILTRATION

|

Precise slot selection is not possible

depending on the size of s in particular area.

|

Due to specialized manufacturing process, wide

range of slot opening is available down to 0.15 mm to allow proper slot

selection depending upon the size of sand in particular area. This gives

better sand control and reduced pump maintenance and longer bore well life.

|

|

CLEANING & MAINTENANCE

|

As the top layer gets choked, the rate of

percolation of water to the well will go down rapidly.

|

Raw water enters horizontally into the screen

assembly and it begins from the bottom of the pit hence all the impurities

will be settled at bottom first.

Due to above phenomena, pit will remain open from the top and recharge

process will be continued more than the conventional system.

|

|

EASY MONITORING & TRANSPARENCY OF FILTER PIT

|

Once the pit is filled with gravels and other

media, it will not be possible to visualize the working process so no

advance actions can be taken to rectify.

|

The operating condition of the filter pit can

be easily monitored so that suitable precautions can be taken if necessary.

|

|

Details

|

VEE-WIRE FILTER SCREEN KIT

|

VEE-WIRE SINGLE FILTER SCREEN

|

|---|---|---|

|

SIZE

|

a) 150 mm dia x 300 mm dia

b) 200 mm dia x 400 mm dia (as per Required Length) |

a) 150 mm dia b) 200

mm dia

c) 250 mm dia d) 300 mm dia (as per Required Length) |

|

SLOT SIZE

|

0.15 mm to 3 mm

|

0.15 mm to 3 mm

|

|

LENGTH

|

0.5 mtr – 3 mtr

|

0.5 mtr – 3 mtr

|

|

END FITTINGS

|

As Per Available Standards

|

As Per Available Standards

|

|

Material

|

SS 304 or LCG as per Customer Requirement

|

SS 304 or LCG as per Customer Requirement

|